ABOUT US

Eagle Jumbo Co., Ltd.

– Leading Manufacturer of Automotive Snow Chains and Forestry Chains

Strong R&D Capabilities:Driving Innovation for Long-Term Solutions

With over 50 dedicated research and development experts and a strong intellectual property portfolio of 60 projects, including 50 utility models and 12 invention patents, we are committed to delivering innovative solutions that directly address our customers’ needs. Our R&D capabilities enable us to:

- Develop tailored products that meet specific industry requirements, ensuring the highest level of performance and reliability.

- Improve product efficiency and reduce operational costs through advanced design and technology.

- Provide solutions to complex challenges in tire protection chains, forestry machinery, and other specialized areas, offering enhanced durability and functionality.

- Continuously upgrade our product offerings to stay ahead of industry trends, giving our customers access to cutting-edge technology.

By leveraging our strong R&D capabilities, we empower our customers to achieve optimal results, solve operational problems, and stay competitive in their respective markets.

Strong Production Capacity to Support Global Demands

Eagle Jumbo Co., Ltd. is equipped with a wide range of world-class production equipment and advanced production lines, capable of manufacturing products ranging from small 2.5mm car chains to large 12-ton tire protection chains. Our factory also produces various forestry chains and logging machine track chains. With a diverse product range and highly efficient production capabilities, we can meet the needs of various industries worldwide.

The company boasts a robust production capacity, ensuring high-volume output and consistent product quality. Our commitment to efficiency and innovation allows us to deliver products that meet international standards, further cementing our position as a leading manufacturer in the industry.

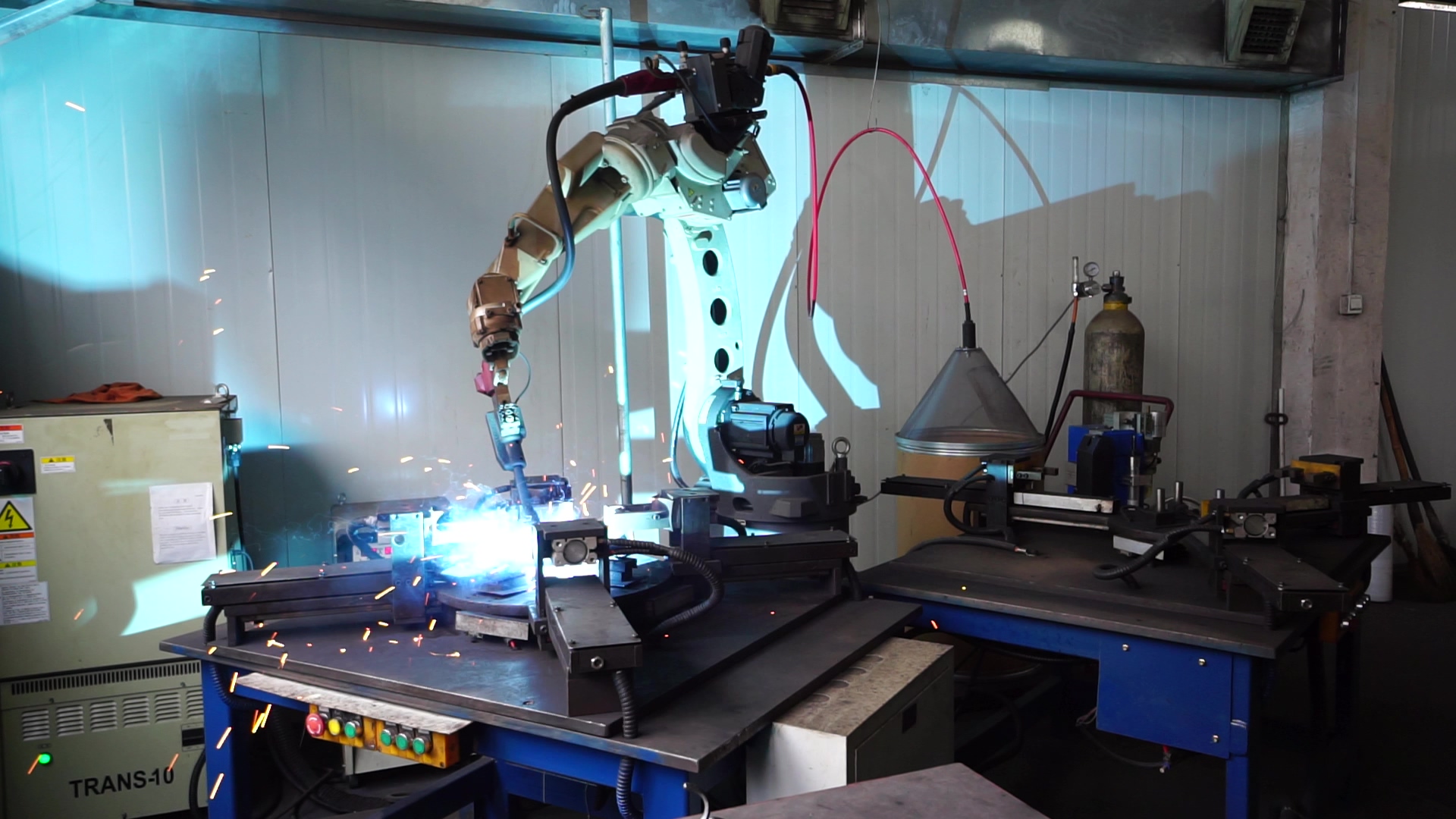

ASEMBLY LINE

90% Automated Production for High Efficiency

Over 90% of our production processes are fully automated, ensuring high efficiency and consistency in manufacturing. This advanced automation significantly reduces production time and labor costs, allowing us to quickly respond to market demand and deliver products on schedule, whether for large orders or urgent custom requests.

Flexible Production Lines for Diverse Needs

With the ability to produce everything from 2.5mm small car chains to large 12-ton tire protection chains, our factory's flexible production lines cater to a wide range of products. This versatility enables us to meet the diverse needs of our global clientele, providing both mass-produced items and specialized, customized solutions.

Robust Quality Control and Precision Manufacturing

strict quality control ensures that each product meets stringent international standards, such as US NACM-TCe and European ONORM5117.V5119 and V5121. The combination of advanced machinery and rigorous testing guarantees that we deliver reliable and high-quality products to our customers.

Quality Inspection

At Eagle Jumbo Co., Ltd., quality inspection is integrated into every step of our production to ensure every tire chain meets the highest standards. Here’s how we prioritize quality as the foundation of our process

Raw Material Inspection

In-Process Monitoring

Comprehensive Testing

Post-Production Quality Assurance

Reliable Tire Chains for Every Vehicle and Industry

Offer your customers high-performance, long-lasting tire chains for all types of vehicles and industrial equipment.